Lithium-ion batteries are at the coronary heart of just about each individual electric auto, laptop computer and smartphone, and they are necessary to storing renewable vitality in the deal with of the climate unexpected emergency. But all of the world’s latest mining operations are unable to extract plenty of lithium and other vital minerals to satisfy skyrocketing need for these batteries. Establishing new mines is an pricey, many years-extensive energy. And mining also results in a host of environmental headaches—such as depleting nearby water resources and polluting the nearby area with runoff debris—that have led to protests from new mines.

All of this suggests the potential to recycle present batteries is critical for sustainably shifting the global power technique. But recycling lithium-ion batteries has only not long ago created industrial inroads. Battery suppliers have hesitated more than worries that recycled solutions might be lower in excellent than those built from freshly mined minerals, possibly leading to shorter battery everyday living or harm to the battery’s innards. Repercussions could be significant, significantly in an software such as an electrical car or truck.

But new investigate released in Joule has strike upon what authorities describe as a more stylish recycling system that refurbishes the cathode—the thoroughly crafted crystal that is the lithium-ion battery’s most pricey component and critical to giving the right voltage. The researchers found that batteries they built with their new cathode-recycling strategy carry out just as perfectly as all those with a cathode produced from scratch. In reality, batteries with the recycled cathode each very last extended and charge quicker. The team’s technique and profitable demonstration are “very exclusive and extremely amazing,” suggests Kang Xu, an electrochemist at the U.S. Military Exploration Laboratory, who was not involved in the study.

A Joke No More

Yan Wang, a components science professor at Worcester Polytechnic Institute and co-author of the new review, started off researching battery recycling 11 many years ago. At the time, he says, “some people joked with me, ‘There’s not adequate batteries for you to recycle.’” That joke is not getting old properly. The Department of Power estimates the battery current market may perhaps develop 10-fold about the subsequent 10 years. To ease the market’s increasing pains, “recycling of lithium-ion batteries—getting that product again into the supply chain—is significant,” claims Dave Howell, director of the DOE’s Car or truck Technologies Business. The DOE funded the new study as aspect of its enormous exertion to spur significant-scale battery recycling improvements in the U.S.

When a lithium-ion battery is supplying electrical power, a cluster of lithium ions moves from a single crystalline “cage” (the anode) to one more (the cathode). The most prevalent approaches now made use of to recycle these batteries contain dismantling and shredding the full battery, then either melting it all down or dissolving it in acid. The outcome is a black mass—with a texture can that can differ from powder to goo—from which chemical features or simple compounds can be salvaged. Individuals recovered products can then go by means of the exact same business producing system that newly mined components do to make cathodes.

Wang and his colleagues use a pretty equivalent process—but as a substitute of entirely breaking the battery down to its constituent chemical components, their technique keeps some of the outdated cathode’s important composition intact. Soon after they shred the battery, they physically clear away the considerably less high-priced bits (these kinds of as the electronic circuits and steel battery casing) and recycle them independently. What is remaining is primarily the cathode material they dissolve this in acid and then eliminate impurities. Future, they very carefully add just a contact of fresh new factors that compose the cathode, such as nickel and cobalt, to guarantee the ratio of components is just right—another difference from frequent recycling approaches. Right after a handful of a lot more steps, the final result is an correctly refreshed cathode powder, composed of tiny crystalline particles that can be caught onto a metallic strip and put in a “new” battery.

Mainly because a cathode is crafted from a specific mix of treasured minerals to attain the battery’s unique voltage, slight variations to its structure or composition can compromise its functionality. Hence, much of the cathode powder’s price is “in how you’ve engineered the particles [of powder] in the very first put,” says Emma Kendrick, a professor of electricity elements at England’s University of Birmingham, who was not involved in the new research. That value is dropped if the complete battery is only melted down or dissolved in just one fell swoop, as in existing recycling solutions.

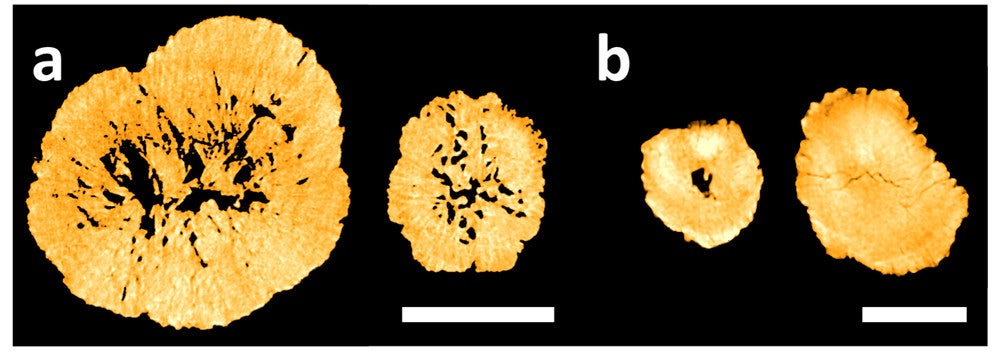

More Pores, More quickly Demand

Wang and his colleagues as opposed the particles in their recycled cathode powder with individuals in commercially manufactured cathode powder (mostly designed from freshly mined minerals). They discovered that the recycled powder particles had been more porous, with specially big voids in the center of every just one. These attributes offer room for the cathode crystal to swell a little as lithium ions squeeze into it, and this wiggle room keeps the crystal from cracking as effortlessly as cathodes created from scratch. These cracking is a big cause of battery degradation over time.

Additional pores also suggest a lot more exposed floor area, where the chemical reactions that are necessary to demand the battery can happen—and this is why Wang’s recycled batteries cost speedier than their commercially manufactured counterparts. A foreseeable future ambition could be to style and design all cathodes to have this excellent structure rather than just people created from recycled stuff, Wang says.

The hottest results reveal that “the cathode they can make is as excellent as—or even better than—the business material that we’ve been importing,” suggests Linda Gaines, a transportation analyst at Argonne National Laboratory and main scientist at ReCell Center, an business that experiments and encourages battery recycling. (Gaines was not involved in the new study.) These kinds of imports mostly come from China, which prospects the globe in battery recycling. But this predicament suggests resources should be shuffled across the world to be recycled, increasing the carbon footprint of recycled batteries and diminishing their allure as a much more sustainable path. The approach developed by Wang’s crew cuts out a important chunk of worldwide trade and transportation requirements, carving a possible path for other international locations to bolster domestic battery recycling. The course of action is currently currently being scaled up by Ascend Things, previously Battery Resourcers, a recycling organization Wang co-launched.